Vibration Analysis

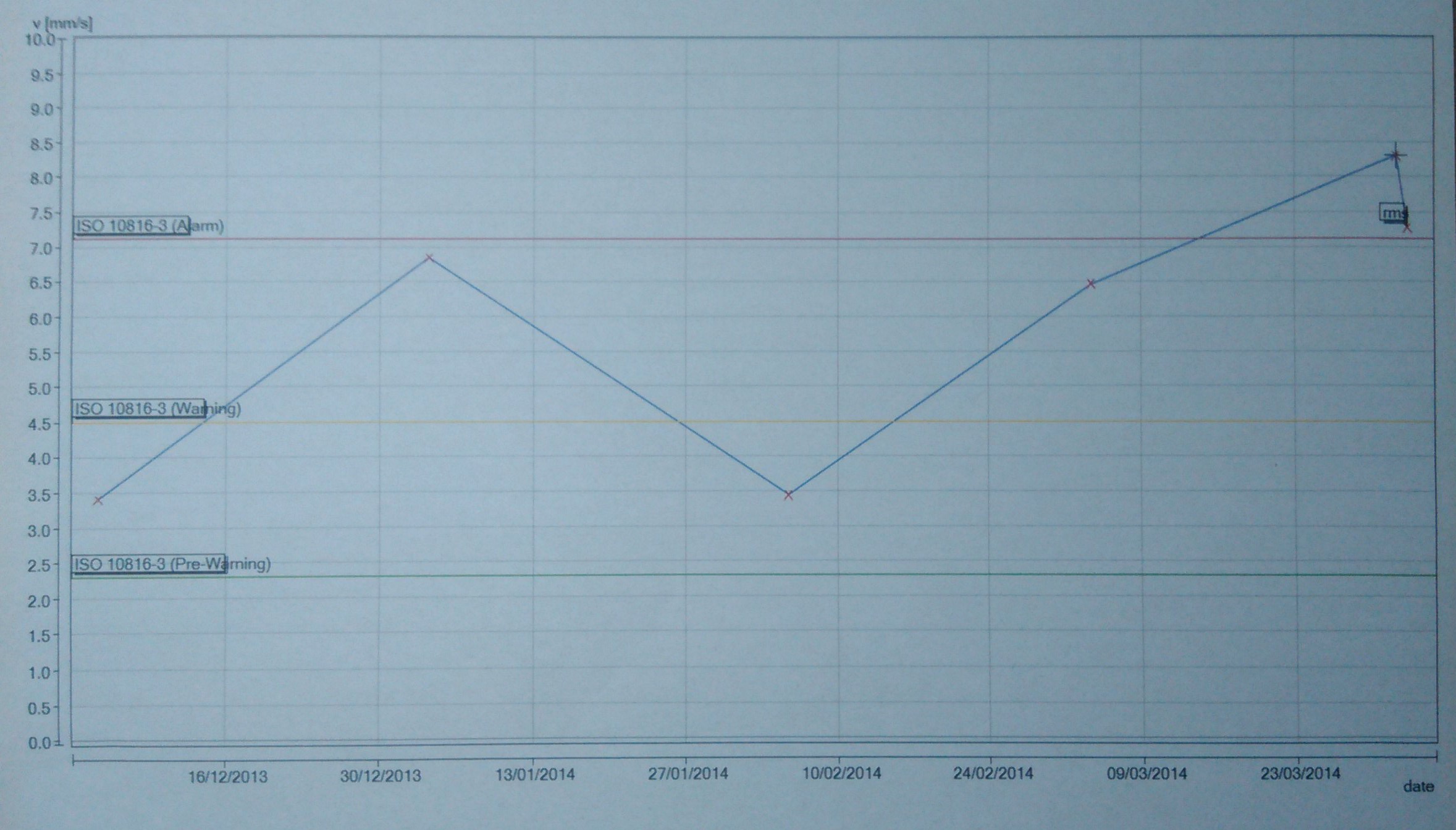

Vibration Analysis is the primary technique used to determine the health of rotating assets. By monitoring vibration levels and trending them over time it is possible to predict and diagnose problems occurring that could lead to asset failure. Identifying these problems early allows time for maintenance to be carried out in a planned manner during scheduled production downtime periods.

Asset Condition Monitoring Ltd use the latest vibration analysis techniques and analysis software to detect such issues as:

- Unbalance

- Looseness

- Misalignment

- Belt issues

- Electrical Issues

- Gear problems

- Inadequate Lubrication

- Bearing Defects

- Cavitation

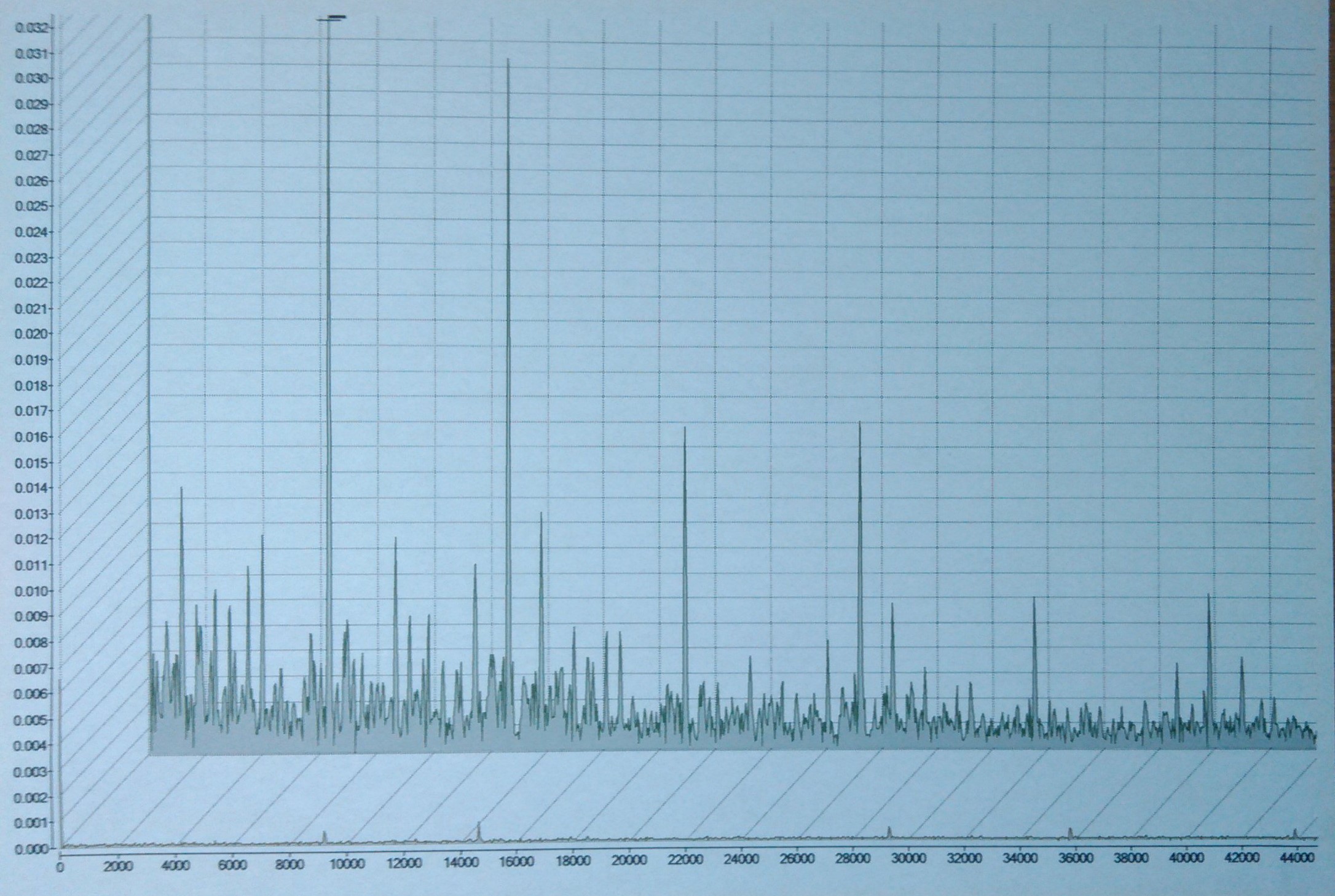

Asset Condition Monitoring Ltd are able to asses your plant and build vibration collection specifications to suit each individual asset. Having built a Hierarchy of assets we will then enter machine details such as bearing type, pulley ratios, gear ratios / No. of teeth, Etc. to enable accurate analysis of all vibration data leading to precise recommendations for your maintenance team.