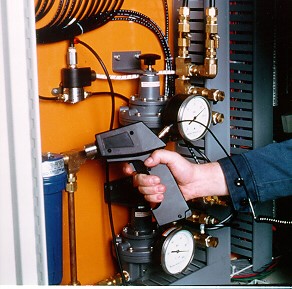

Ultrasound

Ultrasound detection is a valuable technique in Condition Based Maintenance programs and in the reduction of energy costs.

Ultrasound can be detected in structures (with contact probes) or in the air (with airborne probes) to detect issues such as:

- Valve Leaks

- Pressure/Vacuum Leaks

- Steam Trap (Blow-by, machine gunning ..)

- Bearing Deterioration

- Inadequate Lubrication

- Electrical (i.e. arcing, tracking ..)

It is particularly useful as part of a CBM program when detecting bearing deterioration on slow rotating shafts which is not easily identified using vibration monitoring techniques. By using a contact probe, a worn/damaged bearing can easily & quickly be detected and scheduled for maintenance during the next planned shut down.

Energy costs can be significantly reduced by using the airborne probe to detect air leaks from compressed air lines. Compressed air is not free and air leaks cost money. By identifying and sealing these leaks, significant cost savings can be made - year on year !

Asset Condition monitoring Ltd are able to provide you with Ultrasound services as part of a CBM program or for specific investigations such as Air Leak Surveys.